Contents

- 1 Pipe Clamp Manufacturer & Supplier | Stainless steel | Cast Iron

- 2 Investment Casting Pipe Clamp Manufacturer

- 2.1 Clamp casting profile

- 2.2 High-Quality Industrial Pipe Clamps

- 2.3 Stainless steel pipe clamp investment casting

- 2.4 Ductile Iron Saddle Clamp

- 2.5 High Precision Custom Made Pipe Clamp

- 2.6 1. Manufacturing Process:

- 2.7 2. Technical Support

- 2.8 3. Quality Control

- 2.9 Regular package:

- 2.10 Why choose us?

- 2.11 FAQ

Pipe Clamp Manufacturer & Supplier | Stainless steel | Cast Iron

We are a Pipe clamp manufacturer & supplier in China.

We can supply different materials with pipe clamps.

Such as Stainless steel Pipe clamps, cast iron Pipe clamps, and aluminum Pipe clamps.

Carbon Steel Clamp, Ductile Iron Clamp, and other pipe clamp parts.

Clamps can reduce vibration and noise, and enhance the sealing ability.

Clamp product applications are wide and unlimited. Specially customized clamps also can be ODM and OEM as per customers’ needs.

What is a Pipe clamp?

Pipe clamps are devices for fixing pipes or tubes. It is suitable for the fixing of light, medium-weight, and heavy pipelines made from different materials. It can be defined as the support mechanism for suspended pipes. The pipe clamp ensures all pipes are fixed securely and can be used for installing or uninstalling.

Pipe clamps fall under the category of pipe fasteners and are widely used to serve the purpose of securing piping in a variety of installations–especially those concerned with construction and plumbing.

Pipe clamps come in different sizes, materials, and types, with each type having unique mechanical, thermal, and electrical properties. Some common types of pipe clamps are listed below.

Pipe Clamp Classification

- By shape. Full circle heavy pipe clamp. Full round pipe clamp. Long head to half type pipe clamp. Short head to half type pipe clamp. Rotate the pipe clamp. Rotating with a felt clamp. J-type pipe clamps, etc. Double bolt pipe clamp. Galvanized double-hole pipe clamp. Three-hole pipe clamp. Two-piece pipe clamp, sleeve pipe clamp

2. By material. Plastic ABS pipe clamps. Aluminum alloy pipe clamps. Stainless steel pipe clamps. Carbon steel pipe clamps, Cast Iron pipe clamps, etc.

3. By functions:

| Rigid Clamps | Rigid clamps are usually made from hard iron or steel. It makes these clamps suitable for fixture building and allows fast locking and unlocking. Pipes can easily be inserted into these clamps and locked to an accurate position. Rigid clamps closely resemble traditionally styled pipe clamps and are ideal for minimizing leakage. Rigid clamps are often used in the construction of milling and shaping machines. |

| Adjustable Clamps | Steel, aluminum, and plastic often comprise the base material for these clamps. The biggest advantage of adjustable clamps is that they can be used for a wide range of pipe sizes. The size of the clamp can be changed easily by the diameter of the pipe by tightening or loosening the screw attached to the clamp. This allows the clamp to be reused for another pipe that has a different diameter, hence making it economical to buy. |

| Swivel Crossover Clamps | Swivel crossover clamps generally consist of a couple of half fittings which are bolted together. This feature of swivel crossover clamps allows full rotation of the pipes to any desired angle between 0 and 360, making them ideal for crossbracing. These Hengke Metal pipe clamps are generally easy to install and operate and can be used to build racks, railings, and other structures. Moreover, they can be added to existing pipe structures easily without undergoing the hassle of dismantling them. |

| Standard pipe clamps | Hengke Metal Standard clamps are typically fixed using two screws – one on either side of the clamp. They can be lined or unlined, depending on the application and there tends to be a wide range of sizes to choose from. Best for straightforward installations of metal or plastic pipes. |

| Cushioned Clamps | Cushioned clamps have a unique long-lasting and protective cushion that allows protection from marring and corrosion. These clamps can be used for a variety of pipe surfaces, such as wood, metal, and plastic. But they are especially recommended for the clamping and suspension of non-insulated pipes. Using this type often makes clamping easy as it allows a slight difference in pipe size to be compensated due to the flexibility of the cushion. Cushioned clamps prevent corrosion and absorb vibrations and shock. Additionally, these clamps provide noise reduction which may be beneficial during construction. Cushioned clamps are typically manufactured from steel and stainless steel and are easy to install. |

| U-bolt Clamps | Available to fit a range of diameter sizes, u-bolt clamps have 4 components, namely the saddle, U-bolt, and 2 hex nuts. For proper installation, the nuts of the clamp require tightening. Once that is done, these clamps can sustain a tremendous amount of weight. U-bolt pipe clamps can be used to secure a pair of pipes or tubes together and are often referred to as saddle clamps. U-bolt clamps are manufactured from steel, aluminum, and malleable iron castings. |

| Heavy-duty pipe clamps | Heavy-duty clamps have a high safe working load, so are designed for use where heavy load support is required. They can be used indoors and outdoors and are available both with and without lining. They have modern features to make them easier to fit than traditional clamps. Take a look at how Hengke Metal heavy-duty pipe supports were used to secure district heating pipes to the underside of a bridge. Best for safe fixing of heavy load pipework indoors or outdoors. |

| Pipe clamps with rubber lining | Some applications require pipe clamps to have a rubber lining. This is often a requirement due to the material or temperature of the pipe. Lined clamps also offer noise-insulating properties. |

Advantages of Pipe Clamp

We have a vast range of pipe clamps and brackets for fixing pipework, that covers 99% of all known pipe sizes and pipe types. Our pipe clamps have below advantages:

1. High corrosion resistance

Corrosive environments grade is from C1 to C5. C5 is the highest level of corrosion expected. Our pipe clamps cast and fixings are suitable for use in C1-C4 environments. Especially our stainless steel pipe clamp.

2. Easy installation and uninstalling.

We can produce at the client’s request or design it to the customer’s idea. Ensure it is easy to install and uninstall to save time and cost.

3. High technical support and design tools

As a global company, we have invested in state-of-the-art technology which allows us to be as accurate as possible when making calculations and designing effective pipe-fixing installations for our customers.

4. Extreme Quality Inspection

In testing our pipe clamps, we are not only to test appearance, but also in-house test clamps to destruction. So we can ensure the quality!

Investment Casting Pipe Clamp Manufacturer

Clamps investment casting is our advantaged product. We are a China Investment Casting Pipe Clamp manufacturer and supplier. We can produce many kinds of precision casting clamps, pipe steel clamps. If you have investment casting clamp parts purchasing or steel pipe clamp price inquiry. Welcome, contact us freely. The popular types of investment casting clamps are as below. Stainless steel Investment Casting Clamp, Investment Casting Carbon Steel Clamping Parts, Ductile Iron Saddle Clamp. Contact us for the quotation from the pipe clamp manufacturer in China.

Clamp casting profile

| 1. Material percentage | alloy steel:45% carbon steel:35% stainless steel:10% iron:10% |

| 2. Casting weight percentage | 0.1-5kg:40% 5-20kg:30% 20-40kg:20% above 40kg:10% |

| 3. Industry percentage | Components for train & railway: 20% Components for automobile & truck: 35% Components for construction machinery & forklift: 25% Components for agricultural machinery: 10% Other machinery components: 10% |

| 4. Global market share | United States:30% Europe:15% Japan& Korea:35% Domestic market:15% Other:5% |

| 5. Production capacity | Production Capacity: 1,000 tons / year |

High-Quality Industrial Pipe Clamps

Standard: GB/T3091 – 2001, BS1387 – 1985, DIN EN10025, EN10219, JIS G3444:2004, ASTM A53,ASTM A53: GR. A , GR. B,

Steel Grade: Q195, Q235, Q345, S235, S235JR, S355JR.STK400 /500.

Size: 1/2″, 3/4″, 1, 1-1/4″, 1-1/2″, 2″, 2-1/2″, 3″, 3-1/2″, 4″.

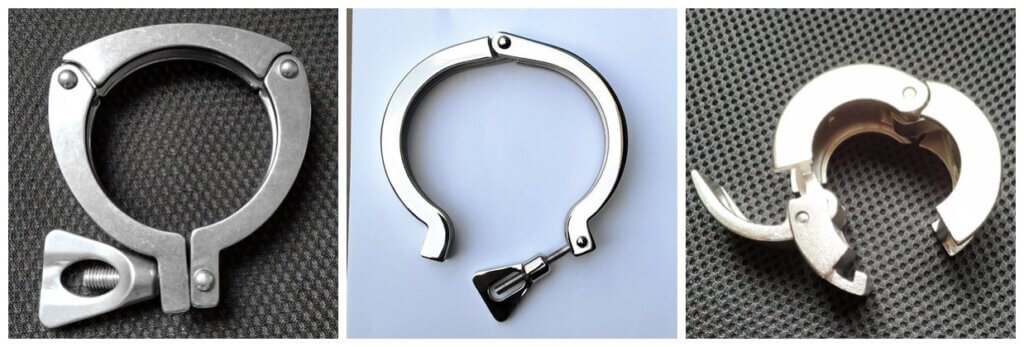

Stainless steel pipe clamp investment casting

| Material | Carbon steel, Alloy steel, Stainless steel, Aluminium, Copper |

| Process | Lost wax casting + CNC machining |

| Casting Tolerance | ISO2768-mK, VDG P690 D1-D2, ISO8062-3-2007 DCTG4-6, GCTG4-6 |

| Casting roughness | Ra1.6-3.2 |

| Machining roughness | Ra0.8-3.2 |

| Casting weight range | 0.005-50kg |

| Material standard | GB, ASTM, AISI, DIN, BS, JIS, NF, AS, AAR…. |

| Surface treatment | Zinc plating, Polishing, Anodizing, Painting, Nickel plating |

| Heat treatment | Annealing, Normalizing, Hardening, Tempering, Case hardening… |

| Service | OEM& ODM |

| Quality Control | ISO9001 |

| Application | Pump & Valve Parts |

Ductile Iron Saddle Clamp

1. Material: Gray Iron, Ductile Iron, Malleable iron;

2. Process: Green sand & Resin sand & Precoated sand;

3. Finish: Antirust oil, Plating, Paint, Powder Coating, etc…;

4. Weight: 0.03 – 50 Kg;

5. Years of experience in manufacturing and exporting pipe clamps.

6. All sorts of casting can be manufactured according to the customer’s requirement, drawing, design, or samples;

7. The coordinated service (casting, machining, and surface treatment) make lower price possible;

8. Strong engineering team makes high-quality;

9. Full material testing process and quality control system;

10. On-time delivery;

11. OEM & ISO;

| Product Name | saddle clamp for steel pipe |

| Size | DN50/PVC63(3/4″-2″)DN300/PVC315(3/4″-2″) |

| Material | Ductile Iron GGG50,GJS500-7,GGG40 |

| Usage | For air, water, sewer, and gas pipelines |

| Pressure | PN10, PN16 |

| Pressure Test | 15Bar, 24Bar, |

| Connection pipe | PVC/PE Pipe |

| Surface Treatment | FBE Coating |

| Payment term | 1.30% TT deposit and 70% TT when the goods are finished but before shipment 2. L/C or D/P |

| Packing | case, pallets, or as per customers’ requirement |

High Precision Custom Made Pipe Clamp

| Product Name | High Precision Custom Made Pipe Clamp | |

| Material | Carbon steel, stainless steel, Two-way stainless steel, alloy steel | |

| Production Process | precision casting | |

| Tolerance | CT 4–6 | |

| Design | According to the customer’s design, ideas and samples; According to the sample, we can provide measurement and drawing | |

| Service | OEM&ODM. Accept trial order | |

| Packing | No fumigation wooden case | |

| Major export markets | The United States, Japan, South Korea, Germany | |

| Certificate | ISO9001 | |

| The Factory History | Since 1997 | |

| Machine equipment | Lathes, CNC, drilling machines, milling machines, boring machines, machining centers, etc | |

| Surface treatment | Painting, spraying, electroplating, electrolysis, polishing, heat treatment | |

| Inspection equipment | Rockwell hardness tester, Vickers hardness tester roughness tester, barometer, concentricity tester, universal microscope, coordinate measuring machine, digital caliper, spectrometer, impact testing machine, etc | |

| Application | Including automobile parts, railway parts, medical parts, ship parts, lighting parts, pump bodies, valve parts, construction parts, and other mining machinery |

1. Manufacturing Process:

Process design⇒ Tooling making ⇒ Wax injection ⇒Wax pattern assembly⇒ Mold preheat ⇒ Wax removal ⇒Stuccoing⇒Dipping Casting⇒ Mold shake out ⇒Workpiece cut-off ⇒ Grinding ⇒ Pack& transport ⇒ Final inspection ⇒Machining ⇒ Heat treatment

2. Technical Support

Hengke Metal is professional in independent development and design. Our engineers are skilled in AUTO CAD, PRO ENGINEER, SOLID WORKS, and other 2D & 3D software. We can design, develop, produce

, and deliver your PO according to your drawings, samples, or just an idea. Dual control of standard products and OEM products.

3. Quality Control

1) Checking the raw material after they reach our factory——- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have a full inspection and routing inspection during mass production—In-process quality control(IPQC)

4) Checking the goods after they are finished—- Final quality control(FQC)

5) Checking the goods after they are finished—–Outgoing quality control(OQC)

3.1 We provide various test facilities as mentioned under:

| 1. Chemical analysis |

| 2. Tensile strength |

| 3. Elongation rate |

| 4. Shrinkage rate |

| 5. Impact test |

| 6. Harness test |

| 7. Metallography |

| 8. Non-destructive tests(including dye-penetrant, ultrasonic, magnetic particle, and radiography) |

| 9. Surface roughness test |

| 10. CMM test |

| 11.3D Scanning |

Regular package:

- Pallets including iron pallets, regular wooden pallets,s and non-fumigation pallets.

- Plastic film inside with an iron cage is for items with a large cubic, and irregular shape.

- Wooden case is high quality to accept more than 1.2ton goods.

- We can provide many different Packing ways according to our customers’ different requirements.

- Packaging: 60pcs per carton, each part be packed by bubble bag, 16.50kgs per carton. 54cartons per wooden case/pallet.

Shipping:

- DHL, UPS, FedEx, etc, 3-5 days, door to door.

- COSCO, MSK, with fast and competitive ocean charges for customers always.

- Train transportation is also available.

- Shipping: By sea from Qingdao/Shanghai, By air from Qingdao, By train from Ningbo….

Why choose us?

- 1. We are a professional supplier, and our products obtained related qualification certification, We warranty no quality issues.

- 2. We will offer a more favorable and reasonable price.

- 3 One-stop source, Any related products may inquire with us.

- 4. We are close to the airport and Qingdao port. The logistics are very convenient.

- 5. We accept many flexible payment terms.

FAQ

Q1. Are you a manufacturer or a trading company?

A1. We are a professional pipe clamp manufacturer with over 15 years of export experience in designing and producing metal castings.

Q2. What is your MOQ?

A2. We are a Pipe clamp manufacturer & supplier in China. We can supply different materials with pipe clamps. Such as Stainless steel Pipe clamps, cast iron Pipe clamps, and aluminum Pipe clamps. Carbon Steel Clamp, Ductile Iron Clamp, and other pipe clamp parts. Clamps can reduce vibration and noise, and enhance the sealing ability. Clamp product applications are wide and unlimited. Specially customized clamps also can be ODM and OEM as per customers’ needs.s according to you, usually, it is 1000 units. We accept small quantities…

Q3. What is the delivery time for the sample?

A3. It is according to the sample, usually, it is 25 to 35 days.

Q4. What is the thinnest wall thickness you can cast?

A4. By special technology, like ceramic core/soluble wax, we can cast the wall thickness at 0.5-0.8mm.

Q5. What is the range of the weight you have cast?

A5. The weight we can cast is from 0.007kg to 80kg.