Hengke Metal is a Marine Casting Industry manufacturer in China. Our main supplying products are Marine Grade investment stainless steel casting s and aluminum castings with high corrosion resistance.

Contents

Marine Casting Materials

In marine casting products, stainless steel casting and aluminum casting are the most common metal forming processes today. Although aluminum casting is lightweight, it has limited corrosion resistance in seawater and requires extensive maintenance. Stainless steel castings have excellent corrosion resistance, gloss, strength, and stiffness. So it becomes the best choice for the marine industry.

Stainless Steel for Marine Applications

For many marine applications, SS 304 castings can be used. But SS316 is the industry standard. It is also called marine-grade stainless steel. Besides 304 316 stainless steel, duplex stainless steel can be used too. They have higher corrosion resistance.

Why Stainless Steel for Marine Applications?

For many marine applications, grade 304 (UNS S30400/S30403) stainless steel castings have proven adequate. The current industry standard, however, is grade 316 (UNS S31600/S31603 – commonly termed “marine grade” stainless) which offers a solution to around 90% of marine applications. Grades 304 and 316 are austenitic (300 series) stainless steels due to their metallurgical structure (austenite) which gives them excellent ductility, good strength, non-magnetic properties, good weldability and very good corrosion resistance.

While stainless steel grades 304, 316 and duplex steels can all be used in marine applications, they do provide varying degrees of corrosion resistance and durability. The corrosion resistance of all stainless steels also improves if they are kept clean.

Marine Casting Method

The Marine Casting method with stainless steel alloys is mainly lost wax investment casting. A stainless steel investment casting process is excellent producing dimensionally accurate and superior corrosion resistance for the marine industry. Such as 316 stainless steel casting, which has good economic sense. At Hengke Casting stainless Steel Foundry, we also offer the second operation and surface treatments. Such as electropolishing, mirror polishing. They can enhance marine casting corrosion resistance more and provide casting’s superior surface finishes.

Marine Casting From Hengke Metal

We can design and manufacture castings for a range of uses in the industry, including:

- Engine components

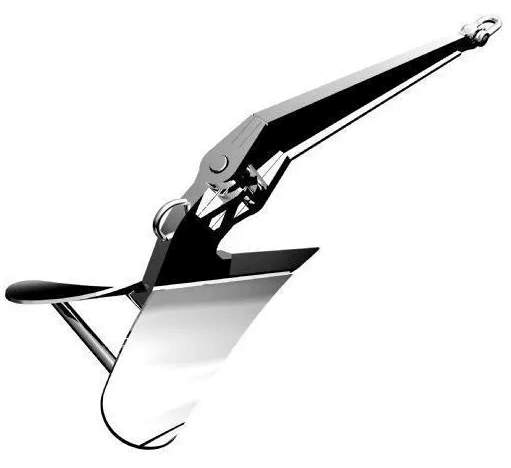

- Bruce boat anchor

- Boat Steering Wheels

- Seal housings

- Pump housings

- Marine cross bollard

- Deck hardware

- Bearing housing

- Boat rail base fittings

- Boat propeller

- Cleats, handles, brackets, covers

- Boat hardware

What we can do?

Hengke Metal mainly supplies custom stainless steel investment casting services to deliver high-quality parts for marine applications.

From concept to finished product, we can produce castings that are made to measure for any marine industry project.

We own rich experience in the stainless steel investment casting process and stainless steel alloy selection to casting marine hardware.

All equipment is an Automatic production line in our foundry with higher production efficiency.

Both large marine parts and small volumes can be offered.

We can offer Post treatments such as heat treating, machining, and surface finishing.

A flexible transportation solution is available too.

The casting method used for marine applications with stainless steel alloys is mainly investment casting. An investment casting process is an excellent option for producing dimensionally accurate hardware that requires superior corrosion resistance for the marine industry. Since many highly corrosion-resistant materials (i.e. 316 stainless steel) are cast on a regular basis, employing this process makes good economic sense. At Hengke Metal, we manufacture thousands of stainless steel investment casting parts each year and have an outstanding track record of doing so in the industry’s fastest lead times at competitive prices. We also have the ability to provide parts with additional surface treatments such as electropolishing, and mirror polishing, to enhance corrosion resistance even more and provide parts with superior surface finishes.

Examples of marine hardware produced by stainless steel casting include:

- Boat propeller

- Boat Steering Wheel

- Boat rail base fittings

- Marine cross bollard

- Bruce boat anchor

- Deck hardware

- Cleats, handles, brackets, covers, and other boat hardware

- Engine components

- Bearing housing

- Seal housings

Marine Stainless Steel Casting Capabilities

Hengke Metal mainly supplies custom stainless steel investment casting services to deliver high-quality parts for marine applications. We are equipped with all the necessary equipment including machining and surface treatments to to provide finished parts.

- Rich experience in stainless steel investment casting process for marine applications.

- Wide selection of stainless steel alloys to cast marine hardware.

- Automatic production equipment in our foundry with higher production efficiency.

- Cast stainless steel marine parts in either large or small volumes can be offered.

- Post treatments such as heat treating, machining and surface finishing are feasible in our foundry.

- We offer flexible transportation solutions for our customers according to their demands.