White Paper: The Benefits of Investment Casting

Contents

What Is Investment Casting?

Investment casting is a metal fabrication technique in which a wax pattern is coated by dipping it in refractory material—usually a ceramic slurry. Once the material is fully coated, it is hardened and then dewaxed to remove the wax. The resulting mold is used to create a design of the desired final piece. Molten metal is then poured into the mold and left to cool and solidify. After the solidification process, the shell is broken to reveal the final piece.

Investment casting is also known as lost wax casting or precision casting. The process is capable of producing metal parts with high dimensional precision and a smooth surface finish. The advantages of precision casting make it a widely used casting process. Accordingly, investment casting applications play a significant role in various industries.

The Investment Casting Process

The investment casting process is a unique vesting technique. The difference is always seen in the mold creation process, which sets it apart from the sand casting and die casting process.

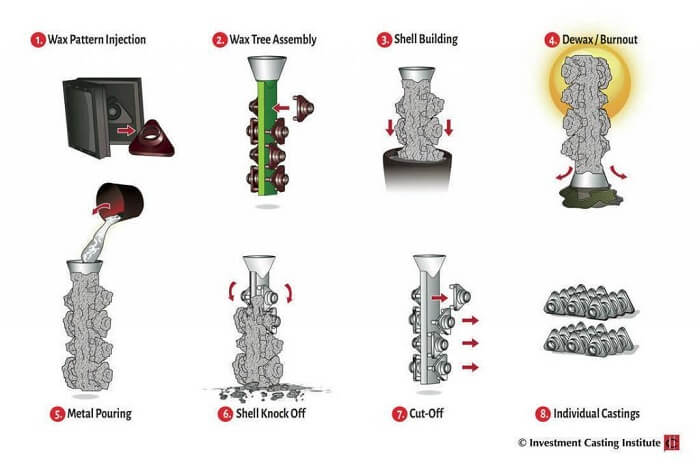

The entire precision casting process can be broken down into the following stages:

- The first stage is usually the pattern creation phase. A metal injection die is used to design the wax pattern. This pattern takes the form of the desired final piece.

- The next step involves the creation of the gating system and runners. This system is the tree system that guides the flow of the molten metal into the mold.

- Once the pattern and the gating system are created, the pattern is dipped in ceramic slurry. The process is repeated severally to make it as hard as possible. The shell is usually dried.

- After the shell has dried, it is heated (dewaxed) to remove the wax.

- Molten metal is then poured into the mold and left to cool. The cooling leads to the solidification of the final piece.

- The shell is then broken to reveal the final piece.

- Since the investment casting process uses a ceramic mold, the final piece comes with a smooth surface finish, which means that post-processes are not required.

Investment Casting Products

Investment casting products are usually small operational pieces of machines. The investment casting process is used in many industries.

In the automotive industry, the investment casting process is used to manufacture various products, such as fans, cams, gears, and other parts with intricate designs. The process is also used to produce jet engine parts and various pieces of medical equipment.

Investment casting is also common in jewelry production, detailed statuary, and other decorative products with smooth surface finishes.

Industries That Rely On the Investment Casting Process

Industries such as oil and gas, automotive, aerospace, and defense require reliable, high-quality components designed to meet specific standards and withstand harsh treatment. Therefore, investment casting companies deliver high-integrity casting parts to meet the demands of these sectors.

For instance, the aerospace industry needs precision casting to manufacture interior and exterior engine components, such as sensors and hydraulic fluid systems. Accordingly, the automotive industry relies on the investment casting process for the production of lightweight components.

The precision casting process is essential in the oil and gas industry to produce components used in the upstream, midstream, and downstream sections.

Many more industries benefit from investment casting. This is mainly because they need reliable, durable, and cost-effective solutions, something the process offers.

The Benefits of Investment Casting

As mentioned, the advantages of precision casting are far-reaching, making it suitable for various applications. Some of the advantages of lost wax casting include.

· Design Flexibility

Investment casting allows for a wide variety of materials, sizes, and configurations. The process offers design versatility and flexibility that allows investment casting manufacturers to produce parts to near net shape.

· Dimensional Precision

The investment casting process produces metal parts with high dimensional accuracy, which eliminates the need for post-processes. This means that finished parts require little to no machining.

· Wide-Ranging Application

As discussed earlier, many industries rely on the investment casting process for various reasons. This means that the technique has a wide range of applications in different sectors. Accordingly, this factor is down to the ability of investment casting to use both ferrous and non-ferrous metals and metal alloys.

· Reduced Lead Times

One of the benefits of investment casting is that it produces parts with smooth surface finishes. Therefore, it eliminates the need for post-processes and machining, which reduces the lead time. In this case, investment casting is essential where time is of the essence.

· Repeatability

Investment casting ensures high-quality products with every production cycle. The process offers very reliable and low-cost repeat runs, which means you can produce any parts over and over again without compromising precision or quality.

· Fewer Defects

The investment casting process ensures high-quality products with fewer defects. This is because the process uses a ceramic mold, which offers near net shape, tight tolerance, and smooth surface finish. However, precision casting has minor defects, which are usually managed through various processes.

· Environmental Friendly

Investment casting eliminates wastage, meaning that little to no metal scraps are released into any landfill. Accordingly, most materials are reused in the production cycle.

The Disadvantages of Investment Casting

Despite the benefits of investment casting, the process has drawbacks that may force you to consider other casting processes, such as sand casting, centrifugal casting, and die casting. The cons of precision casting include:

- Investment casting is suitable for producing smaller parts with intricate designs and shapes. Metal components that exceed 75 pounds may require other casting processes.

- Investment casting is limited in depth. For instance, the process may not be suitable for manufacturing parts that are deeper than 1.5 times the diameter.

- Lastly, investment casting is more complex than other casting processes.

The Bottom Line

When it comes to producing different parts, every manufacturer will require a method that meets precise specifications. Many casting methods can be used. However, investment casting stands above them with the ability to offer smooth surface finishes, intricate designs, and reduced lead times.

The advantages of investment casting are many. All of which allow investment casting manufacturers to meet specific requirements.